Fertilizers and plant nutrition products have always travelled a long road before reaching the farm or greenhouse. Traditionally, bulky sacks, rigid drums, or simple plastic bottles dominated the scene. While these formats served their purpose for decades, they rarely aligned with the evolving needs of modern horticulturists, professional growers, and even home gardeners. The recent surge in purpose-built pouches is not just a packaging upgrade - it’s reshaping how plant nutrition products are stored, shipped, dispensed, and experienced.

The Demands of Modern Agriculture

Agriculture today is a blend of science, logistics, and business acumen. With increasing pressure to maximize yields while minimizing environmental impact, precision matters at every step. Fertilizers and micronutrient blends must arrive intact and uncontaminated. Consistent dosing can mean the difference between a bumper crop and wasted investment.

Custom packaging for plant nutrition products has stepped up to meet these demands. Where once generic sacks sufficed for bulk fertilizers, companies now seek packaging that preserves efficacy over time and supports safe handling practices. This shift isn’t isolated - it mirrors trends across adjacent sectors like agricultural seeds custom packaging, animal feed custom packaging, and chemicals custom packaging.

How Purpose-Built Pouches Solve Old Problems

When I first visited a commercial greenhouse in the late 2000s, I watched as workers lugged heavy bags of granular fertilizer across damp floors. Inevitably some material spilled or clumped due to humidity exposure. At another facility relying on liquid foliar feeds stored in drums, operators struggled with precise dosing - often resorting to guesswork.

Purpose-built pouches address both these pain points:

- Barrier Protection: Modern multi-layer films shield contents from oxygen and moisture ingress better than traditional sacks. Dosing Convenience: Spouted or pre-measured pouches allow accurate portioning. Reduced Waste: Resealable closures help prevent clumping or spoilage when partial quantities are used. Transport Efficiency: Flexible pouches weigh less and use space more efficiently than rigid containers.

The result is less product lost to spoilage or mishandling - something both large-scale growers and hobbyists appreciate.

Evolving Materials: Beyond Simple Plastics

Not all pouches are created equal. Material selection defines performance as much as design does. For instance, high-barrier laminates incorporating layers of PET (polyethylene terephthalate), aluminum foil, and PE (polyethylene) provide robust protection against gas exchange. Some companies opt for compostable films derived from cellulose or PLA (polylactic acid), especially in markets with strong sustainability norms.

A European supplier specializing in food supplements custom packaging shared that their migration to fully recyclable pouch laminates reduced annual landfill contributions by about 20 tons across their client base. In regions where chemical regulations drive tight scrutiny on leachables or extractables (such as California’s Prop 65), pouch liners may require certification to ensure no contamination reaches the fertilizer blend.

Formats That Fit Every Application

Walk any agricultural supply expo and you’ll see an expanding array of pouch formats tailored for specific tasks:

- Stand-up spouted pouches dominate liquid fertilizers intended for pump-action dispensers. Flat sachets work well for single-use microbial inoculants or micronutrient powders. Gusseted bags offer higher volume capacity without sacrificing shelf footprint. Child-resistant zipper closures are common for household gardening products with regulated ingredients.

A manufacturer serving both sports nutrition custom packaging and plant nutrition clients explained that consumer familiarity with flexible single-serving packs helped drive acceptance among weekend gardeners who want easy-to-use feeding solutions.

The diversity doesn’t end at shape or closure type - branding matters too. High-resolution digital printing allows even short-run batches to feature vivid graphics that communicate usage instructions clearly while reinforcing company identity.

Regulatory Realities: Not Just About Looks

Plant nutrition products occupy a regulatory gray zone between foodstuffs and industrial chemicals depending on local rules. Packaging must comply with varying standards around labeling language, traceability codes (such as QR or Data Matrix), tamper evidence features, and sometimes US Packaging Company child resistance.

One anecdote stands out: A US importer faced customs delays when their European-sourced seaweed extract arrived in unmarked retail-style pouches rather than bulk drums labeled per EPA guidance. What seemed convenient became costly as pallets sat idle awaiting relabeling.

Companies supplying medical custom packaging or pharmaceutical custom packaging already navigate such complexity daily; lessons learned there increasingly inform best practices in fertilizer pouch design too.

Sustainability Is More Than Buzzwords

For years sustainability claims focused on recycling symbols stamped onto rigid containers or vague promises of “eco-friendly” materials. Flexible pouches invite deeper scrutiny because multilayer structures can be hard to recycle conventionally unless facilities exist to separate components.

Yet the overall carbon footprint often tips in favor of flexible formats when lifecycle analysis includes transport emissions (due to lighter weight) or warehouse storage efficiency sustainable packaging supplier (thanks to compact stacking). Some vendors now offer take-back programs tied to subscription box custom packaging models - encouraging users to return empties for closed-loop processing.

A practical example comes from a Dutch hydroponics supplier whose move from HDPE jugs to barrier pouches cut monthly outgoing freight volumes by nearly a third without increasing breakage rates during shipping custom packaging operations.

Cross-Pollination: Lessons From Other Sectors

Packaging innovation rarely happens in isolation. Developments pioneered in one segment quickly find fans elsewhere if they solve universal problems:

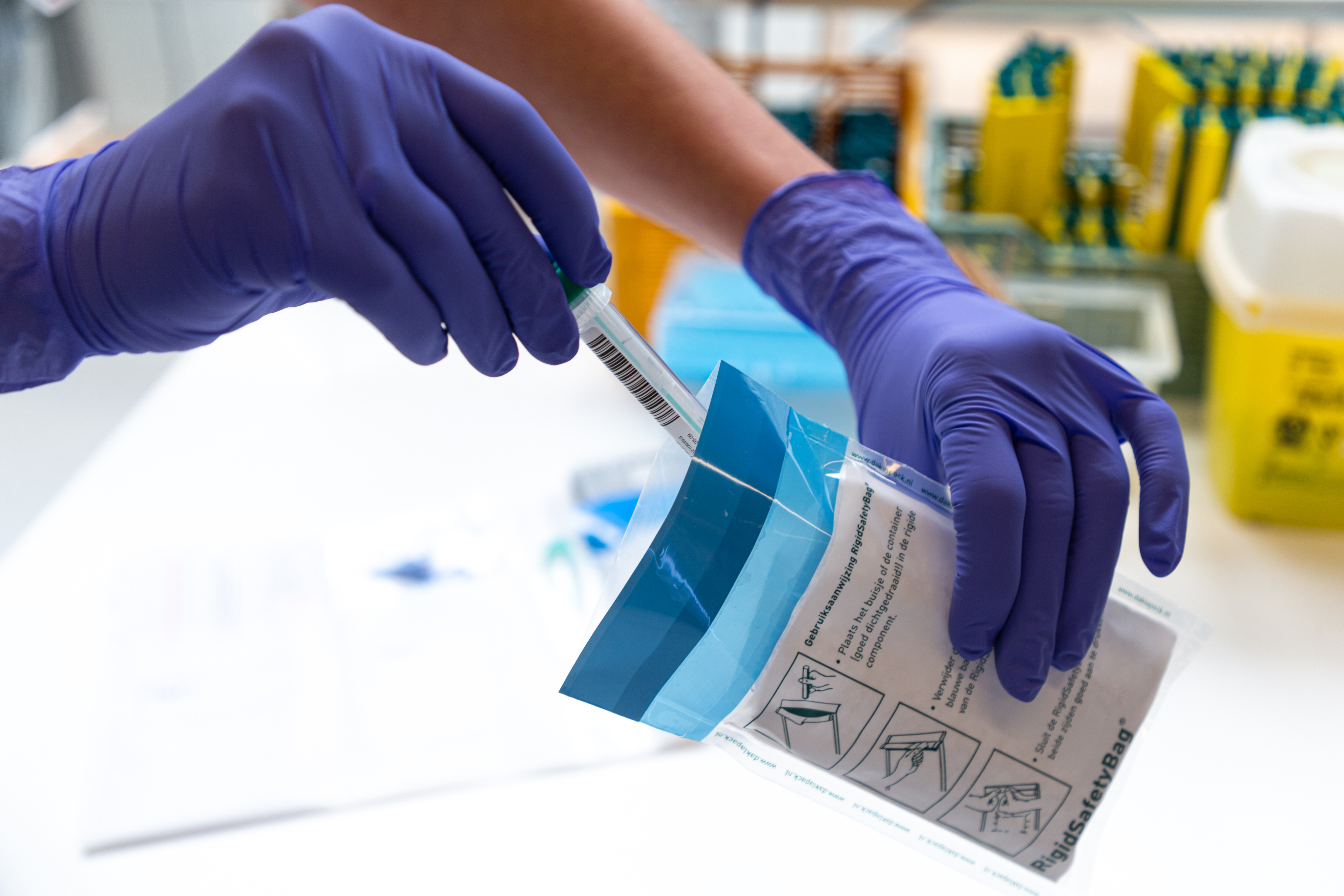

- Cannabis & CBD custom packaging set new standards for aroma preservation using metallized liners now adapted by organic fertilizer brands seeking odor containment during storage. Personal care custom packaging drove advances in soft-touch matte finishes that make handling easier even with gloved hands - useful when dealing with dusty plant powders. Diagnostics system suppliers custom packaging popularized tamper-evident seals that have migrated into premium biostimulant offerings where purity is paramount.

Biotech firms formulating living microbial consortia need sterile barrier integrity akin to pharmaceutical-grade conditions; their choice of pouch film composition echoes what’s common in hospital custom packaging circles.

Practical Trade-Offs: No One Size Fits All

Despite clear benefits, purpose-built pouches do not suit every scenario equally well:

Bulk agricultural clients still prefer large woven polypropylene sacks when cost per kilogram is paramount and automation handles filling/emptying at scale. Drums retain advantages for certain corrosive concentrates where rigid walls resist puncture risk during rough handling by medical logistics providers custom packaging professionals moving hazardous goods daily.

On the flip side, smallholder farmers piloting specialty nutrient blends often value resealable stand-up pouches precisely because they lack access to climate-controlled storage spaces; here shelf life trumps unit cost considerations.

What works best depends on product chemistry (liquid vs powder vs gel), distribution chain realities (distance traveled, climate variation), regulatory context (child resistance mandates), and end-user expectations around convenience versus price sensitivity.

Real-World Example: A Microbial Inoculant Rollout

In 2022 I advised a startup launching an innovative consortium of nitrogen-fixing bacteria aimed at greenhouse tomato growers across Europe’s Mediterranean belt. Their initial plan called for glass vials inside cardboard sleeves - classic laboratory fare but impractical outside controlled environments due to weight and breakage risk during transit handled by 3PL custom packaging partners unfamiliar with fragile goods.

After several design iterations involving sample shipments via airfreight during peak summer heatwaves (over 30°C ambient temperatures common along southern routes), they shifted toward high-barrier laminated flat sachets with integrated desiccant strips inside secondary foil-lined mailers. Field feedback revealed significantly fewer failed deliveries compared to glass vials; growers praised both ease of opening sachets while wearing gloves and ability to reseal unused portions without contaminating live cultures inside remaining packs.

This experience mirrored lessons from veterinary custom packaging specialists who routinely balance sterility concerns against flexibility needs for clinics ordering small batch treatments on short notice.

Beyond Function: Branding Opportunity Beckons

No discussion would be complete without acknowledging how purpose-built pouches enhance brand storytelling far beyond what plain sacks ever could offer:

Vivid full-color graphics communicate mixing ratios instantly regardless of language barriers - vital for global brands selling into dozens of markets simultaneously through resellers custom packaging channels. Matte finishes paired with embossed logos elevate premium-positioned products above commodity competition sitting side-by-side on retailer shelves. Window panels let buyers inspect granule size or color without breaching package integrity; this transparency reassures quality-conscious customers accustomed to cosmetic-grade presentation standards seen in beauty & skincare custom packaging sectors. QR codes unlock video tutorials demonstrating optimal application techniques right at point-of-use - bridging gap between instruction manuals easily misplaced after purchase versus information delivered direct via smartphone scan. At every touchpoint the pouch becomes more than container - it’s part educator, part ambassador.

Checklist: Key Features When Specifying Plant Nutrition Pouch Packaging

When evaluating options alongside your packager or supplier representative:

Confirm compatibility of inner film layers with product chemistry (acidic liquids need different barriers than dry powders). Assess resealability requirements based on typical dose size versus package capacity. Ensure closure system meets relevant safety regulations if restricted compounds present (child resistance may be mandatory). Factor transport/storage climate variability into laminate thickness selection; humidity swings demand robust moisture barriers. Prioritize clear labeling space for legally mandated declarations plus instructional graphics tailored to user skill level.Even seasoned procurement teams occasionally overlook details like vent holes needed when filling hot liquids into flexible packs; real-world trial runs remain invaluable before full-scale launch.

Looking Ahead: Room For Further Innovation

As plant health management grows more sophisticated - think biostimulants harnessing soil microbiome dynamics or slow-release chelated micronutrients dosed via drip irrigation systems - so too will demands placed upon their delivery vehicles.

Expect integration between smart labels tracking lot provenance via blockchain tech borrowed from pharma supply chains; interactive elements embedded within D2C custom packaging experiences blending printed materiality with app-based guidance tailored per user profile; ongoing improvements around recyclability as waste management infrastructure catches up with complex laminates now standard industry-wide.

The journey from basic sackfuls toward bespoke barrier-laminated pouches illustrates more than changing tastes; it signals how every link along the value chain now expects better protection, clearer guidance, reduced waste streams - all wrapped up quite literally in smarter packages.

For those bringing next-generation fertilizers or bioactives to market today whether targeting hobbyist gardeners shopping online through ecommerce custom packaging platforms or commercial agronomists placing pallet orders via established distribution networks investing upfront in purpose-built pouch solutions pays dividends long after first shipment leaves the line.

The humble pouch has come a long way since its debut as mere convenience wrapper; now it sits at the intersection of science-backed performance, regulatory compliance rigor, end-user empowerment… all while quietly keeping crops greener behind the scenes.